Turner Drone Team Works with Crane and Rigging Group to Complete Sky-High Project

Turner Drone Team Works with Crane and Rigging Group to Complete Sky-High Project

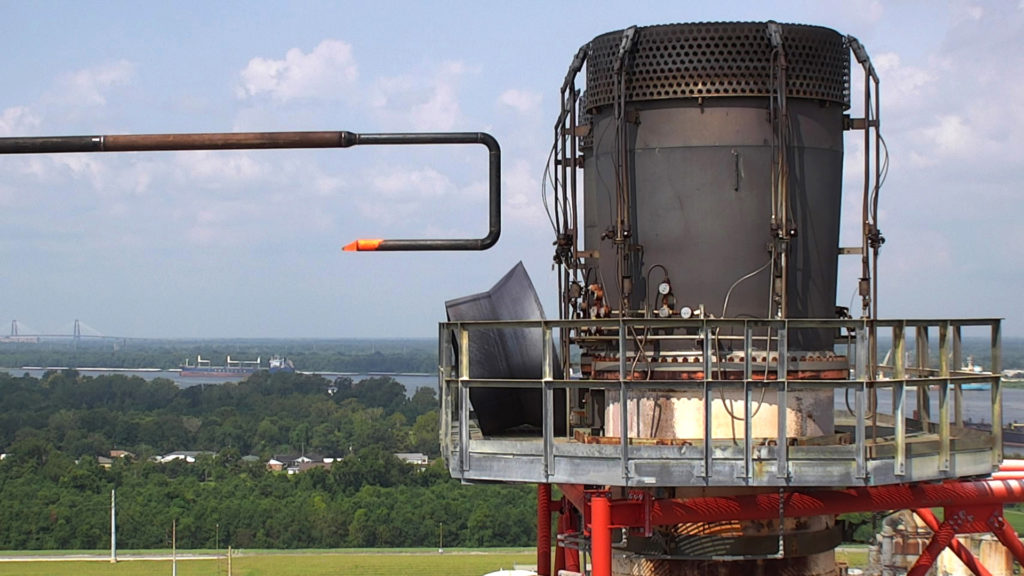

In late August, Turner Industries crane and rigging group was contacted by a chemical facility for guidance on recovering a velocity ring that had been dislodged and expelled from one of their flare tips. During the group’s first site visit, it was discovered that the velocity ring was resting on the top deck right next to the site’s 200 ft. tall operating flares. These unique circumstances warranted a collaboration with Turner Specialty Services’ (TSS) NDE & inspections group to help further assess the situation and develop a safe lift plan. The TSS thermography team was able to determine that the flares were operating at 1,500 degrees Fahrenheit, which eliminated the use of our standard rigging hardware, which is rated for use only up to 1,000 degrees. In addition, TSS’s Unmanned Aerial Vehicle group (UAV) used their DJIM210, with a 30x optical zoom camera attached, to provide a 360-degree view of exactly how the ring was positioned on the deck. The rigging crew used the drone images and heat info to draw up a custom cantilever beam that would recover the ring and bring it to the ground while keeping the crane’s boom tip a safe distance from the flare. The drone images also enabled the plant to determine exactly where the ring became dislodged so they could begin to correctly reduce the flare temperatures for recovery day.

Once the cantilever beam drawings were finalized by our rigging engineers, the equipment yard welding shop built, tested, and certified the beam within ten hours. At the same time the 500 Ton Liebherr hydraulic crane was assembled onsite with 253′ of luffing jib to lift the newly fabricated cantilever beam. When it was go-time for recovery, a TSS thermographer was onsite monitoring the flare temperatures while two licensed UAV pilots flew drones to survey the lift. This assistance allowed the crane operator and rigging supervisor to monitor what was happening in real time, watching the drone footage on an iPad as the lift was made. In just under five days after the initial call, the ring was recovered from the flare deck and, on the first try, set safely on the ground. This one-of-a-kind project and unique Turner collaboration is a prime example that there is nothing we cannot accomplish when we work together.